Description

We provide the world's largest size commercially available GaTe crystals at the highest quality GaTe and affordable prices. Our crystals exceed competing crystals both in size and quality.

Description

Our single crystal monoclinic GaTe (Gallium telluride) crystals come with guaranteed anisotropy, electronic, and optical grade crystal quality. They are developed at our facilities using three different growth techniques, namely Bridgman growth, chemical vapor transport (CVT), and flux zone growth, to optimize grain sizes and reduce defect concentrations. In contrast to commonly used chemical vapor transport (CVT) technique, flux grown crystals are well known for their structural perfection and electronic/optical performance. Bridgman and flux zone methods both offer similar grade qualities. Each crystal very large in size to last for years, is highly crystalline, oriented in 0001 direction, and easy to exfoliate. Our R&D staff takes characterization dataset in each sample piece to ensure structural, optical, and electronic consistency.

Properties of monoclinic GaTe vdW crystals

| Crystal size | >1 cm in size and perfectly 0001 oriented |

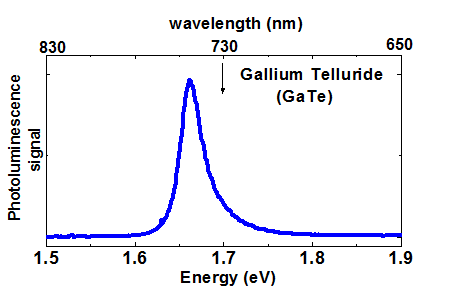

| Material properties | 1.65 eV direct semiconductor (bulk) |

| Crystal structure | Monoclinic (anisotropic) phase |

| Unit cell perameters | a=0.416 nm b=0.934 nm, c=1.086 nm, α=106.05 β=90, y=102.8° |

| Growth method | Bridgman Growth [Optional CVT or Flux zone growth also available] |

| Purity | Better than 99.9999% confirmed |

Growth method matters> Flux zone or CVT growth method? Contamination of halides and point defects in layered crystals are well known cause for their reduced electronic mobility, reduced anisotropic response, poor e-h recombination, low-PL emission, and lower optical absorption. Flux zone technique is a halide free technique used for synthesizing truly semiconductor grade vdW crystals. This method distinguishes itself from chemical vapor transport (CVT) technique in the following regard: CVT is a quick (~2 weeks) growth method but exhibits poor crystalline quality and the defect concentration reaches to 1E11 to 1E12 cm-2 range. In contrast, flux method takes long (~3 months) growth time, but ensures slow crystallization for perfect atomic structuring, and impurity free crystal growth with defect concentration as low as 1E9 - 1E10 cm-2. During check out just state which type of growth process is preferred. Unless otherwise stated, 2Dsemiconductors ships Flux zone crystals as a default choice.

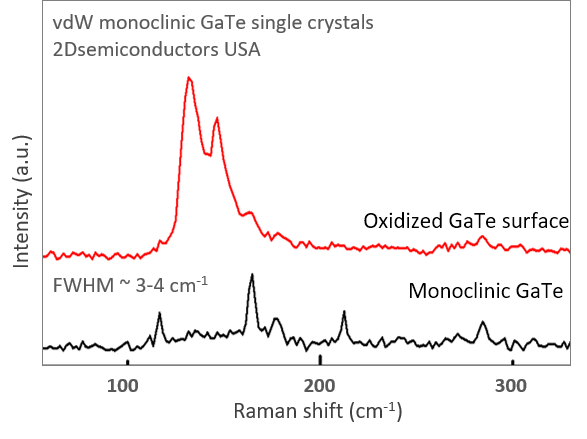

Raman spectrum collected from GaTe vdW crystals

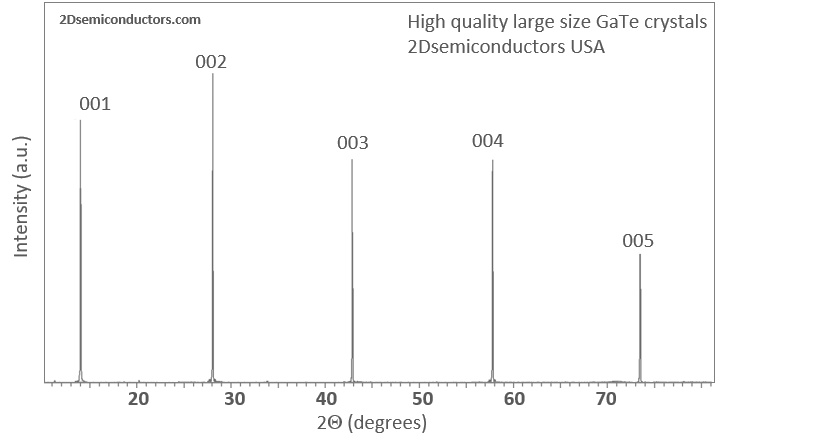

XRD data collected from monoclinic GaTe crystals - 2Dsemiconductors USA

HRTEM images taken from monoclinic GaTe crystals - 2Dsemiconductors USA

Photoluminescence spectrum collected from vdW GaTe crystals - 2Dsemiconductors USA

Additional Information

Elements: |

Ga,Te |

Element: |

Gallium |

Element: |

Tellurium |

Formula: |

GaTe |

Material class: |

MX |

Material class: |

Quasi-1D |

Properties: |

Semiconductor |

Band gap range: |

IR |

Growth method: |

Bridgman |

Growth method: |

Flux |

Growth method: |

CVT |

Doping: |

Undoped |